![]()

Leading Supplier & Exporter

![]()

Trustseal Verified

![]()

ISO Certified

![]()

Manufacturer

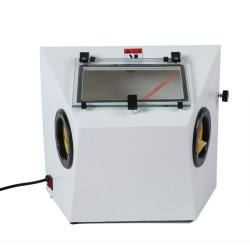

The unique design of Mini Shot Blasting Machine offers maximum versatility. It employs a novel pressure feed system to propel finely graded abrasive powder into a high pressure air stream and out through the nozzle and handpiece assembly. Although it lacks the precision controls of the Shot Blasting Machine series, it can be used effectively for a wide range of applications, including cutting, deburring, etching, surface texturing, surface finishing, glass engraving, glass etching, glass beading of machined parts, preparation of fossils, gems, minerals, artifacts, and much more.

Mini Shot Blasting Machine is the small version of Portable Shot Blasting Machine which is very convenient and easy to use anywhere we want. A Mini Shot Blasting Machine constructed by high quality Blast Pot with the toughest steel sheet for a longer life. It has a simple design and fewer joints for increased durability and it continues blasting for upto 30-40 minutes as per situation.

It is suitable for all abrasive materials including sand, steel shots, aluminum oxide, walnut shells, and so on. A Mini Shot Blasting Machine is frequently used by small and medium-sized businesses such as paint shops, auto repair shops, powder coating shops, floor and surface cleaning service providers, and many others.

We are in great demand for Shot Blasting Machine Manufacturers in India. We manufacture all types of Shot Blasting Machine for various types of Industries in India as well as other countries. We provide top notch quantity products with durability and low maintenance cost. Keeping in mind the needs of small and medium-sized businesses that rely on shot blasting on a daily basis to clean and remove contaminants from various types of metal and concrete surfaces, we have mastered the art of manufacturing Shot Blasting Machine and Mini Shot Blasting Machines in India.

We provide a wide range of Shot Blasting Machine and Abrasive Media such as Portable Shot Blasting Machine, Automatic Shot Blasting Machine, Shot Blasting Cabinet, Mini Shot Blasting Machine, Steel Plate Shot Blasting Machine, etc. and abrasive media like Glass Beads, Copper Slag, Silicon Carbide, Garnet Sand, Quartz Sand, Steel Shots, Steel Grit, Stainless Steel Shots, White Aluminum Oxide, Aluminum Oxide Grit, Aluminum Oxide, etc.

We have assembled a dedicated team of professionals who use high-quality raw materials and cutting-edge technologies installed on our premises to produce bulk goods in a timely and cost-effective manner. We have managed to follow ethical business practices and a reasonable pricing policy to ensure complete customer satisfaction, and we intend to maintain our prompt delivery schedules in the future to ensure client retention.

We provide the most affordable Shot Blasting Machine Price in India. We established ourselves as a dependable exporter, manufacturer, and supplier of Shot Blasting Machines, Shot Blast Rooms, Surface Preparation Equipment, Dust Collector and other related products. These are designed to meet the varying needs of metal polishing, cleaning, and smoothing in industries such as automotive, foundry, construction, rail, and shipbuilding.

We are also experts in manufacturing Sand Blasting Machine, Portable Sand Blasting Machine, Sand Blasting Cabinet, Grit Blasting Machine, Granite Engraving Machine, Sand Blasting Room, Automatic Sand Blasting Machine, Cylinder Shot Blasting Machine, Table Type Shot Blasting Machine and other blasting machines.

Applications of Shot Blasting Machine are:-

Strips off Paint and Corrosion: This is the main purpose of shot blasting. It is common knowledge that paint and corrosion marks are difficult to remove using traditional cleaning methods. Shot Blaster is capable of removing stubborn paint and rust, as well as other contaminants, from cars, houses, machines, and other surfaces.

Cleans Smaller Tools: This important process can also be used to clean smaller instruments such as automobiles and metal tools. Rusted screwdrivers and wrenches, for example, can be quickly cleaned by sandblasting. To ensure efficient operation, Steel Shots blasting machinery that has become clogged with oil, dirt, and grease. Aside from that, cleaning prevents machine breakdown and wear and tear.

Smooths and Polishes Devices: While the primary function of shot blasting is cleaning, the process also leaves surfaces shiny and polished. On occasion, small mechanical parts made of metal and plastic will have rough burrs or other irregularities that make assembly impossible. Sandblasting not only polishes surfaces, but it also removes burrs, tags, and excess material to ensure productive assembly. Furthermore, it smooth edges to achieve the desired surface shape.