Industries

We supply shot blasting machines in the casting industry, forging industry, automobile industry for cleaning, abrasive blasting, corrosion cleaning.

Export

All of our products are exported using multiple ways and incoterms like EXW, FOB, CIF, CIP, DIP, and many more as per requirements. We export our product in each and every country possible under the lawsuits using these methods of transportation.

Our Mission

Our shot blast team have been working in the shot blasting industry for the last 15 years. We provide the good and best service before and after blasting machines order according customers.

About Us

We are the leading manufacturers & suppliers of shot blasting machine, shot blasting cabinet, shot blast rooms, portable shot blasting machine. We have a committed team of skilled strategists and people with exceptional talent Team Sandblast Machine are adaptable and completely capable of reducing uncertainties and providing prompt solutions.

-

Shot Blasting Machine Price In India

We provide shot blasting machine at an affordable & low price in India and all over the world like UK, US, China, Japan, UAE.

-

Shot Blasting Machine Manufacturers In India

We are the best shot blasting machine manufacturers of portable shot blasting machine, automatic shot blasting machine, airless shot blasting machine, shot blasting cabinet in India.

-

Shot Blasting Machine Supplier

We are supplier of shot blast machine, shot blasting machine, shot blast rooms, shot blasting cabinet, shot blasting equipment, portable shot blasting, dustless shot blasting, etc in India.

Our Product

Tumblast Shot Blasting Machine

The tumblast shot blasting machine operates by tumbling work-pieces inside a rotary drum or conveyor as high-speed shot blasting media usually steel shots or grits are forced by shot blasting wheels. The abrasive media effectively cleans & finishes the elements in a closed-loop system, authorizing for batch processing of numerous parts simultaneously.

Monorail Shot Blasting Machine

A monorail shot blasting machine is a technical piece of equipment utilized in surface treatment processes, especially for cleaning, descaling, and preparing metal surfaces. It is widely employed in industriousness like automotive, aerospace, construction, and manufacturing to schedule metal components before painting, coating, and also other processing.

Shot Blasting Wheel

These high performance blast wheels are specially designed for optimum performance and are at the heart of the shot blasting machine. Each shot blasting wheel is clearly recognized by a number and the wheels are specially positioned on the cabin housing to assemble the most effective and effective blast pattern possible.

Manganese Tiles for Shot Blasting Machine

Manganese Tiles are special parts used in shot blast machines to protect their inner surfaces from being worn out. They are made of high manganese steel which is very hard-wearing and durable. That's why they can stand against the abrasive forces during the process of the airless shot blasting machine.

Aluminum Cut Wire Shot

Aluminum Cut Wire Shot are widely used in many industrial tasks for surface treatment. They're essentially tiny wire pieces made from top-quality metal. Their main role is in cleaning blasts, finishing surfaces, and deburring procedures to effectively eliminate unwanted elements and enhance the surface quality of various cast and forged items.

Call To Action

We are the leading Shot Blasting Machine suppliers in India providing all types of shot blasting equipment and machinery. Feel free to reach out to us, our team will be more than happy to solve your queries.

Call To ActionOur Blogs

Automatic Sand Blasting Machine

We are Automatic Sand Blasting Machine Manufacturers in India, provide Sand Blasting Machine, shot blasting machine, pressure blasting cabinet, suction blasting cabinet at low Price in India.

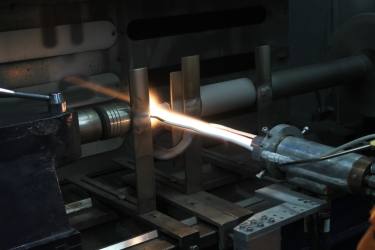

Model JP-5000 HP HVOF System

It is well knowledge that MODEL JP-5000 HP HVOF system provide coatings with excellent adhesion, low porosity, and high density. As a consequence, coatings that perform better and endure longer are created.

HVOF Thermal Spray Coating

The abbreviation HVOF means "High-Velocity Oxygen Fuel." It is a method of thermal spray coating used to apply functional and protective coatings to a variety of surfaces, most frequently metals, ceramics, and composites.

HVOF Coating for Downhole Tools

In order to improve the performance and lifespan of components, such as downhole equipment, high-velocity oxygen fuel (HVOF) coating is a specialized surface coating process that is often employed in numerous sectors, including oil and gas.

Frequently Asked Questions