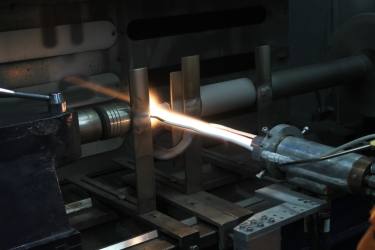

It is well knowledge that MODEL JP-5000 HP HVOF system provide coatings with excellent adhesion, low porosity, and high density. As a consequence, coatings that perform better and endure longer are created. When better surface characteristics are required, a variety of goods, including industrial machinery and aerospace parts, can be coated with MODEL JP-5000 HP HVOF coatings. The MODEL JP-5000 HP HVOF systems allow you to choose the material that is appropriate for your application since they accommodate a variety of materials, including metals and ceramics. The MODEL JP-5000 HP HVOF coatings are suitable for materials that are susceptible to high temperatures because they have a smaller heat-affected zone and less oxidation than coatings applied using conventional thermal spray techniques.

MODEL JP-5000 HP HVOF coatings are the best choice for usage on components that are subjected to abrasive or erosive conditions because to their high wear resistance. Many of the MODEL JP-5000 HP HVOF coatings offer high levels of corrosion protection for components exposed to harsh environments. Depending on the coating material selected, MODEL JP-5000 HP HVOF coatings may be created to offer certain qualities like electrical conductivity, thermal insulation, and more. By protecting them from abrasion, corrosion, and other forms of deterioration, coatings applied with MODEL JP-5000 HP HVOF coating systems lengthen the lifespan of components. Less frequent maintenance and replacement of MODEL JP-5000 HP HVOF-coated components leads to less downtime and higher operating efficiency.

It is well knowledge that MODEL JP-5000 HP HVOF systems provide coatings with excellent adhesion, low porosity, and high density. For a number of applications, including those involving metals, alloys, and ceramics, users of the "JP-5000 HP MODEL JP-5000 HP HVOF System" may be able to choose the optimum coating material. The MODEL JP-5000 HP HVOF coatings are the best option for protecting components from corrosive or abrasive conditions because of their exceptional wear resistance. The coatings produced by the method may offer high levels of corrosion resistance, making them suitable for use on components exposed to corrosive or harsh chemical environments. Depending on the application, the "JP-5000" may allow for the customization of attributes like electrical conductivity, thermal insulation, and more.

For materials susceptible to high temperatures, MODEL JP-5000 HP HVOF coatings are essential since they exhibit reduced oxidation and heat-affected zones as compared to certain other coating processes. Modern MODEL JP-5000 HP HVOF systems usually include tight control over parameters including gas ratios, powder feed rate, and spray distance to ensure consistent coating quality. The "JP-5000 HP MODEL JP-5000 HP HVOF System" might incorporate features to increase combustion efficiency, resulting in fewer emissions and a more environmentally friendly process. Components coated with MODEL JP-5000 HP HVOF systems often have longer lifespans because of the protection provided against wear, corrosion, and other types of degradation. The surface finish of HVOF or thermal spray coating is usually smoother than that of other thermal spray processes.